Environmental Regulation

Regulation for GHG Emissions

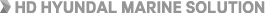

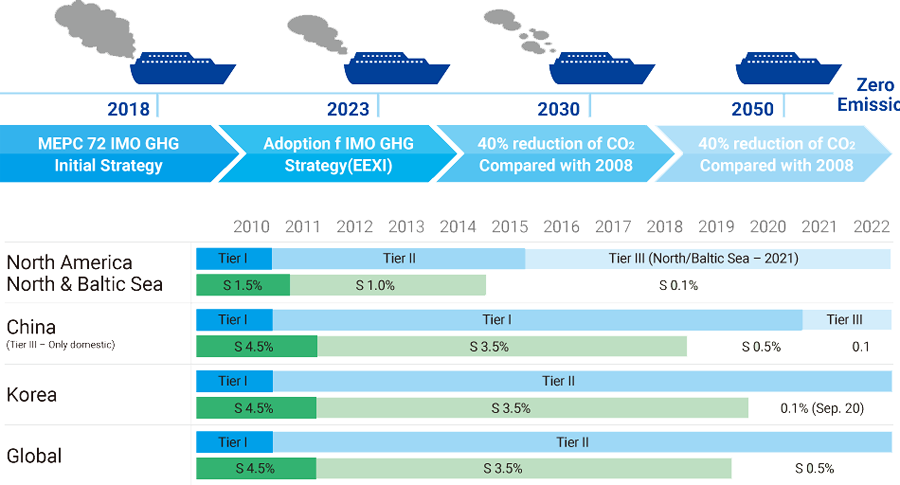

The initial IMO strategy for reduction of GHG emissions from ships are finalized and adopted.

Reduction per transport, as an average across international shipping, at least 40% by 2030, pursing effort towards 70% by 2050, as compared to 2008.

Reduce the total annual GHG emissions at least 50% by 2050 as compared to 2008.

The adoption of revised IMO strategy will be decided at the MEPC 80th meeting (Spring, 2023)

GHG Emissions

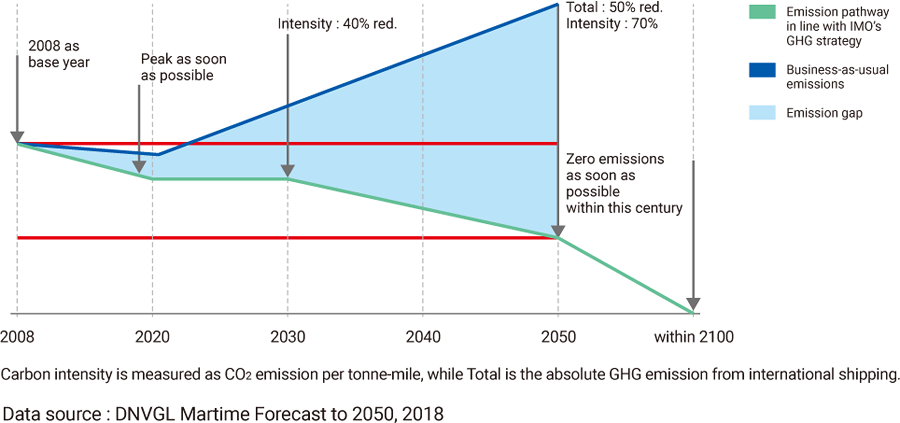

Regulation for SOx Emissions

MAROL revision banning of loading HFO (higher than 0.5% Sulfur oil) on the scrubber unequipped vessel was opted.

According to the sulfur cap regulation decided by the MEPC(Marine Environment Protection Committee) at October 2016, Global marine fuel’s sulfur content standard has been enhanced from 3.5% to 0.5% since January 2020.

Shipbuilding & Marine industry has to select the solutions such as Scrubber, LNG retrofit, or using low sulfur fuel oil to meet the regulation, ahead of the implementation of the most powerful global environmental regulation.

Scrubber fitted vessel is only permitted to use high sulfur fuel otherwise, it is highly prohibited to load high sulfur fuel on board. HGS has been providing customer-oriented service to meet every customers needs

by expanding business area not only supply and installation of Scrubber but also LNG retrofit and suppling low sulfur fuel from bunkering service which take over at June 2016.

Regulation for NOx Emissions

The NOx control requirements of Annex VI apply to installed marine diesel engine of over 130 kW output power other than those used solely for emergency purposes irrespective of the tonnage of the ship onto which such engines are installed.

Definitions of ‘installed’ and ‘marine diesel engine’ are given in regulations 2.12 and 2.14 respectively. Different levels (Tiers) of control apply based on the ship construction date, a term defined in regulations 2.19 and hence 2.2,

and within any particular Tier the actual limit value is determined from the engine’s rated speed :

Touch Scroll

| Tier |

Ship construction date on or after |

Total weighted cycle emission limit (g/kWh)

n = engine’s rated speed (rpm) |

| n < 130 |

n = 130 - 1999 |

n ≥ 2000 |

| I |

1 January 2000 |

17.0 |

45·n(-0.2)

e.g., 720 rpm – 12.1 |

9.8

|

| II |

1 January 2011 |

14.4 |

44·n(-0.23)

e.g., 720 rpm – 9.7 |

7.7 |

| III |

1 January 2016 |

3.4 |

9·n(-0.2)

e.g., 720 rpm – 2.4 |

2.0 |

Touch Scroll

| Tier |

Ship construction date on or after |

Total weighted cycle emission limit (g/kWh)

n = engine’s rated speed (rpm) |

| n (rpm) < 130 |

130 ≤ n < 2000 |

n ≥ 2000 |

| I |

1 January 2000 |

17.0 |

45·n(-0.2)

e.g., 720 rpm – 12.1 |

9.8 |

| II |

1 January 2011 |

14.4 |

44·n(-0.23)

e.g., 720 rpm – 9.7 |

7.7 |

| III |

1 January 2016 |

3.4 |

9·n(-0.2)

e.g., 720 rpm – 2.4 |

2.0 |

NOx Reduction Solutions

The solution to meet the nitrogen oxide emission limit is

low pressure LNG propulsion ships, electric propulsion ship, fuel-cell propulsion ship, hybrid ship, nuclear propulsion ship, EGR (Exhaust Gas Recirculation), SCR (Selective Catalytic Reduction), etc.

HHI-EMD-TT-001 Training Tariff

HHI-EMD-TT-001 Training Tariff

HHI-HSM-SL-12-005 Improvement of Idle Gear of 6H17/28 (with Tuning Wheel)

HHI-HSM-SL-12-005 Improvement of Idle Gear of 6H17/28 (with Tuning Wheel) HHI-HSM-SL-12-007 Improved Connecting Rod Against Fretting for HiMSEN Engine, H32/40(V)

HHI-HSM-SL-12-007 Improved Connecting Rod Against Fretting for HiMSEN Engine, H32/40(V) HHI-HSM-SL-12-008 Proper Tightening Check of the Stud Bolt for Fuel Oil Filter Top Cover, H21/32

HHI-HSM-SL-12-008 Proper Tightening Check of the Stud Bolt for Fuel Oil Filter Top Cover, H21/32 HHI-HSN-CL-12-003 Improvement of Questionnaire System for Field Service

HHI-HSN-CL-12-003 Improvement of Questionnaire System for Field Service HHI-MAN-SL-12-002 The Embrittlement of Electric Cable Insulation HYUNDAI-Main Engine & Generator Engine Built in 2000 to 2005

HHI-MAN-SL-12-002 The Embrittlement of Electric Cable Insulation HYUNDAI-Main Engine & Generator Engine Built in 2000 to 2005 HHI-HSP-SL-12-003 Improvement of Lub. Oil Filter Control Valve for H25/33

HHI-HSP-SL-12-003 Improvement of Lub. Oil Filter Control Valve for H25/33 HHI-HSN-CL-12-002 Renewal of HHI-EMD Customer Service Official Website “Hi-Service”

HHI-HSN-CL-12-002 Renewal of HHI-EMD Customer Service Official Website “Hi-Service” HHI-HSP-SL-12-002 Damage of O-Ring for Fuel Valve bush & Exhaust Valve Insert (EA0143)

HHI-HSP-SL-12-002 Damage of O-Ring for Fuel Valve bush & Exhaust Valve Insert (EA0143) HHI-WCH-SL-12-004 Seat of Electric Motors for Auxiliary Blowers RTA/ RT-flex 82 Engines

HHI-WCH-SL-12-004 Seat of Electric Motors for Auxiliary Blowers RTA/ RT-flex 82 Engines